The 40th anniversary of National Union in Quang Tri Province

Top News

Mr. Nguyen Quan Chinh, Vice Chairman, People's Committee of Quang Tri Province came to visit the site of LED installation.

SUNday - 12/10/2014 19:19

- Viewed: 4389

Strengthening policies to promote energy efficiency in corporations

On 17th September, a workshop was organized with the theme "Energy saving and government policies for businesses", within the framework of the International Conference and Exhibition on "Experiencing Green Energy and Energy Efficiency 2014", held by the Ministry of Industry and Trade in collaboration with Schneider Electric Corporation in Vietnam.

According to Mr. Cu Huy Quang, specialist of Office of energy saving, Ministry of Industry and Trade in his speech at the seminar, the intensity of energy use in Vietnam is 1.7 to 1.8 times higher than that of other countries in the region and from all over the world. It means that in order to make a product, the Vietnam enterprises now have to use the energy consumption that is 1.7 to 1.8 times higher in comparison with other corporations in the world.

This situation has significantly affected the selling price of products, reduced the competitiveness of goods on the market, as well as put pressure on the government agencies in the management of energy use.

However, the potential of energy saving in Vietnam is still very high. Especially, the potential in industries such as cement, iron, steel, brick, ceramic, porcelain ... can reach over 30%.

In Vietnam, energy saving and energy efficiency activities have been implemented and have achieved positive results since the Law on Energy Efficiency and Conservation (Law No. 50/2010/QH12) was promulgated along with related Decrees and Circulars. In particular, the bases of key energy use are the important target groups.

In 2011, Vietnam had 1,190 companies using key energy among 500 thousand enterprises across the country. Despite the mere 0,238% of the total number of businesses, these units consumed 60% of total energy consumption.

According to the latest statistics, as of 2013, there were 1,720 key energy using units. It is predicted that the demand for energy will be constantly increasing. Therefore, the measures of energy saving and efficiency being applied in the key businesses are expected to deliver high efficiency.

In addition to the implementation of the provisions of the Law for related activities, the bases of key energy use also take responsibility in appointing their energy managers and conducting mandatory audits once every 3 years.

For energy audit activities, according to Mr. Quang, businesses can choose service of an energy audit firm or self-audit. The advantage of self-audit is that businesses can understand thoroughly the business process and technology, machinery and manufacturing equipment. However, the disadvantage of this activity is the difficulty in finding the intensive measures for energy saving implementation.

In addition, the key energy using establishments are also responsible for making plans of energy saving and efficiency, reporting directly through the website of the System of national database on energy.

Each unit will be provided with an address in the system with an ID number for access to the basic files on the system.

The workshop also introduced the roadmap and target groups of the energy labeling program as well as the handling of administrative violations in energy management in the industrial bases.

By Yen Pham

Source: tietkiemnangluong.com.vn

Newer articles

- New catalyst could improve biofuels production (20/10/2014)

- Strengthening policies to promote energy efficiency in corporations (20/10/2014)

- EVNNPC, the cradle of Vietnam’s power industry (20/10/2014)

- A new turning point for Ly Son (16/10/2014)

- Da Nang has replaced A92 petrol with biofuel since November (12/10/2014)

Older articles

- 1,720 key energy-using establishments in Vietnam (07/10/2014)

- Small steps at home giant leap for energy saving (07/10/2014)

- 5 restaurant redesigns to reduce energy costs (03/10/2014)

- Implementing energy efficient projects in construction sector (24/09/2014)

- Lai Chau Hydropower Plant project to be completed (24/09/2014)

Devices

Consultancy

Energy Audit

ONLINE

(0909.901.045)

Energy Audit

ONLINE

(0909.901.045)

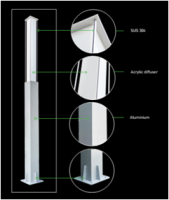

| MOU SIGNING CEREMONY ABOUT SPECIAL LED WITH COB TECHNOLOGY FOR FISHING SHIPS BETWEEN QUANG TRI PPC AND NEDO |